Minerals Local Plan Issues and Options consultation

Minerals provision

Aggregate minerals - estimating future demand

Aggregates make a significant contribution to the construction industry, accounting for around 90% of the total materials used. In Great Britain, around 225 million tonnes are consumed every year. Sustaining this level of demand is of national concern and raises significant planning and environmental issues.

Nottinghamshire has historically been a significant producer of the sand and gravel in the East Midlands, due to the high quality deposits found in the Trent and Idle River Valleys. The majority of the sand and gravel is used in the production of concrete. Building and asphalting sand is produced from the Sherwood Sandstone resource but in much smaller quantities. Nottinghamshire's limestone production is very small compared to the regional output, reflecting the County's limited resource of this mineral.

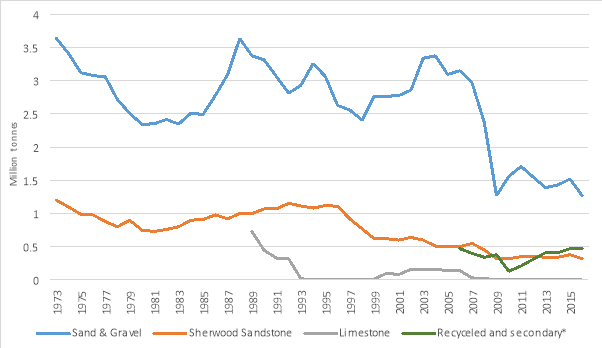

Recycled and secondary aggregates are also produced, however reliable data for this sector is limited. Figure 1 below shows aggregate sales from Nottinghamshire.

Figure 1 Aggregate production in Nottinghamshire 1973 – 2016

(* Estimated data for Recycled and Secondary aggregates)

The recent decline in production illustrated in Figure 1 reflects the impact of the economic downturn on the construction industry which has seen aggregate production fall to record lows.

National Policy on aggregate provision - demand forecasting

National policy requires each mineral planning authority to provide a steady and adequate supply of minerals through the preparation of an annual Local Aggregates Assessment based on a rolling average of 10 years sales data and other relevant local information. Minimum 'landbanks' of permitted reserves are also required to be maintained. For sand and gravel and Sherwood Sandstone the minimum landbank is 7 years (per mineral), for crushed rock the minimum is 10 years.

Based on the evidence set out in the most recent Local Aggregates Assessment which includes 2016 sales data, the demand forecast for each aggregate mineral is set out in Table 1.

Table 1 Nottinghamshire's proposed demand forecast

|

|

Average 10 years sales (million tonnes) |

|

Sand and gravel |

1.7 |

|

Sherwood Sandstone |

0.37 |

|

Crushed rock (limestone) |

0.005 |

What will be the shortfalls over the Plan period?

Using the average sales data set out above, Nottinghamshire will need to provide 32.3 million tonnes of sand and gravel over the Plan period. Once existing permitted reserves are taken into account this leaves a shortfall of 17.8 million tonnes. For Sherwood Sandstone, 7.03 million tonnes will need to be provided over the Plan period. Once permitted reserves have been taken into account, the shortfall stands at 3.3 million tonnes. There is no shortfall for crushed rock.

Table 2 Demand for minerals over the plan period

|

|

10 years sales average (million tonnes) |

Requirement over the 19 year plan period (million tonnes) |

Existing permitted reserves (million tonnes) |

Shortfall over the plan period to 2036 (million tonnes) |

|

Sand and gravel |

1.7 |

32.3 |

17.5 |

17.8 |

|

Sherwood Sandstone |

0.37 |

7.03 |

3.73 |

3.3 |

|

Crushed rock |

0.005 |

0.095 |

3.34 |

- |

Is this forecast robust?

The Local Aggregates Assessment published in October 2017 concluded that the average 10 year sales figure (covering the period 2007-2016) is considered the most appropriate basis for identifying future aggregates demand in Nottinghamshire, as there are no local circumstances which warrant a different approach.

The recession saw significant falls in the sales of aggregates at the national and local level. In Nottinghamshire this was particularly evident for sand and gravel as can be seen in Figure 1.

Taking account of the wider context, although the UK was formally in recession during 2008 and 2009, the effects on aggregates sales were felt until 2012. From this point onwards, sales at the national and East Midlands level have steadily increased. This suggests that demand for aggregates has increased, however for Nottinghamshire this is not the case as sales have remained flat and declined in 2016. This factor is likely to be combined with the minerals industry focusing on existing quarries outside the County and the lack of investment in new greenfield quarries in Nottinghamshire, even though adequate sand and gravel resources remain.

It is recognised that there may be alternative methodologies for calculating future demand for aggregates extraction in Nottinghamshire. We would therefore be interested to hear from individuals or organisations who can provide evidence as to why a different methodology could be more appropriate.

(29) Q4 Do you think the average 10 year sales figure is the most suitable methodology for forecasting future aggregate demand in Nottinghamshire? If not please identify any alternatives you feel are realistic and deliverable and the evidence to support this approach.

(18) Q5 Do you think the same methodology (most recent average 10 year sales) should be used for each aggregate or is there merit in using different methodologies for different aggregates?

Strategic approach to new mineral development

In line with national guidance, the sustainability of minerals development is key to planning for future needs. Given that minerals can only be worked where they are found, extensions to existing permitted quarries can enable the best use of the minerals. This is because the infrastructure to work and process the mineral is already in place and in some cases remaining reserves, which might not be viable to be worked on their own, can also be extracted.

However, extensions to existing quarries can result in potential social and/or environmental cumulative impacts in the area. National guidance states that potential sites should be based on their individual merits taking into account the need for the mineral, economic considerations, the potential positive and negative environmental impacts and the cumulative impacts of proposals in the area.

The Minerals Local Plan will need to identify site specific allocations for some mineral types that are in principle suitable for future minerals development, to provide a steady and adequate supply of minerals over the Plan period.

The choice of potential sites will be influenced by the minerals operators who acquire the rights to work the mineral, and they will have to demonstrate that the site is deliverable (the County Council does not get involved in the purchase of land for minerals development or in the actual working of the minerals). A call for sites will be undertaken as part of the evidence gathering process.

Depending on the availability of extensions to existing permitted quarries going forward, the suggested approach for the Minerals Local Plan will be to give priority to extensions to existing permitted quarries before new greenfield quarries are considered.

(34) Q6 Do you think extensions to existing permitted quarries should be prioritised over new greenfield quarries?

(19) Q7 Should different approaches (new sites/extensions to existing permitted quarries) be adopted for individual mineral types?

Sand and gravel provision

Based on the demand estimates set out in the previous section, the new Minerals Local Plan will need to provide an additional 17.8 million tonnes of sand and gravel reserves in order to meet estimated demand over the plan period to 2036.

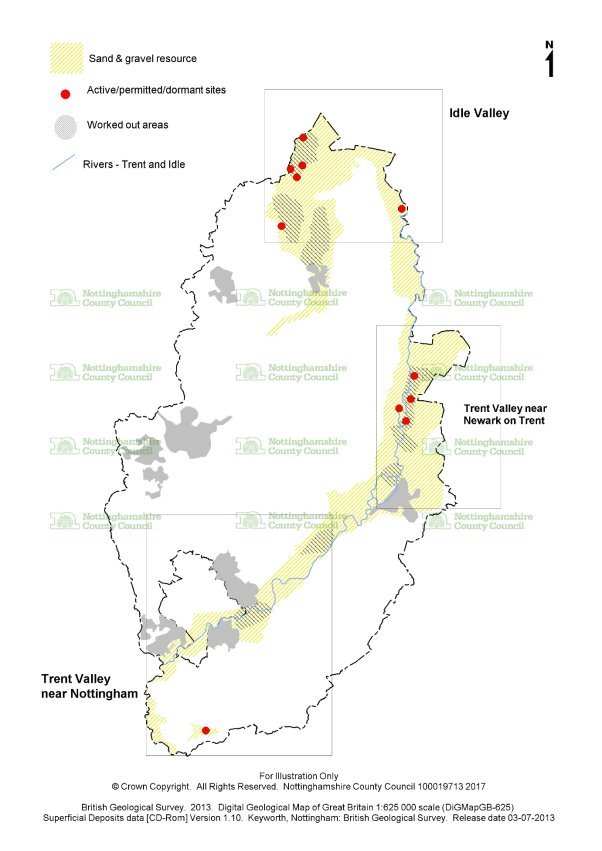

In geological resource terms, adequate resources exist in Nottinghamshire to meet this estimated demand. However as minerals can only be worked where they are found this puts pressure on those areas naturally abundant with sand and gravel. As a result, sand and gravel extraction in Nottinghamshire has historically been concentrated in the Trent Valley near Nottingham, to the north of Newark and in the Idle Valley (see Plan 3).

Maintaining this geographical spread in the future would minimise the social and environmental impacts of quarrying on individual areas and provide minerals close to the main markets, reducing the distances sand and gravel will have to be transported by road. However, as sand and gravel reserves continue to be worked out it will be important to understand whether or not an adequate geographical spread can be maintained over the new Plan period.

Demand for sand and gravel from the wider Nottingham conurbation has historically seen quarries located close to the conurbation. This historic pattern started to break down as no new quarries have been opened to replace worked out quarries in this area. However, sand and gravel resources still exist, it is possible that over the next plan period new quarries could be opened around the Nottingham conurbation. A planning application for a quarry at Mill Hill, near Barton in Fabis, has been submitted to the County Council for determination. No decision has yet been taken, however, if approved the quarry would provide around 3.4 million tonnes which could serve the South Nottinghamshire area and the wider Nottingham conurbation.

A number of quarries are currently being worked near Newark. This area can theoretically serve a wide area including Nottingham, Mansfield and Ashfield and Rotherham and Doncaster due to the good road links (A1, A46, A617). Looking to the future, additional sand and gravel resources remain in this area and could be worked to contribute to overall demand.

The Idle Valley in the north of the County is well placed to serve the north Nottinghamshire markets and the Rotherham and Doncaster markets, and has traditionally done so. However in the longer term this is not sustainable as the sand and gravel resource in the Idle Valley is becoming worked out limiting future choices.

The concentration of sand and gravel production along the Trent Valley also has significant potential to impact both positively and negatively upon the distinctive biodiversity, archaeology and landscape character of this area. Therefore it is important for these issues to be considered when deciding on locations for future workings.

Given the location of some sand and gravel quarries alongside the River Trent, the potential exists to transport mineral by river barge, particularly over longer distances. Barge transport has historically been used to transport sand and gravel along the River Trent to Yorkshire and Humberside from Besthorpe quarry north of Newark, although this has not been used in recent years. Past studies have shown that there is potential to increase water-borne freight on parts of the river. For sand and gravel quarries, barge transport would have the potential to reduce the number of HGV movements.

(34) Q8 How important is it to maintain a geographical spread of sand and gravel quarries across the County (i.e. Idle Valley, near Newark and near Nottingham) to minimise the distance minerals are transported to markets?

(34) Q9 Would it be more appropriate to prioritise specific areas above others?

(31) Q10 Is it economical to transport mineral by river barge and if so should proposed quarries with the potential for moving sand and gravel by river barge be prioritised over other proposals?

Plan 3 Geographical spread of sand and gravel quarries in Nottinghamshire

Sherwood Sandstone provision

Based on the demand estimates set out in the previous section, the new Minerals Local Plan will need to provide an additional 3.3 million tonnes of Sherwood Sandstone to meet estimated demand over the plan period to 2036.

In geological resource terms, adequate Sherwood Sandstone resources exist in Nottinghamshire and it is likely that extensions to existing permitted quarries will be sufficient to meet expected demand. Current production is spread amongst a number of permitted quarries worked between Nottingham and Mansfield and north of Worksop.

A planning application has been received by the County Council for an extension to the existing permitted Bestwood II quarry which would secure an additional 1.4 million tonnes of sand over a 10 year period. If planning permission is granted this will further reduce the required shortfall over the Plan period.

Current evidence indicates that no significant issues are thought to exist for Sherwood Sandstone provision over the Plan period.

A call for sites will be undertaken as part of the evidence gathering process which will identify new quarries or extensions to existing quarries that the minerals operators wish to be considered for inclusion in the Minerals Local Plan.

(9) Q11 Are you aware of any other issues relating to Sherwood Sandstone provision that should be considered through the Minerals Local Plan review?

Crushed rock (limestone) provision

Around 80 million tonnes of crushed rock is extracted in Great Britain each year making it the largest aggregate mineral extractive industry in the Country, with the majority used as an aggregate in the construction sector. Although the East Midlands is one of the most important crushed rock producing areas, Nottinghamshire's resources are relatively limited with only one permitted quarry at Nether Langwith.

Nether Langwith Quarry serves as a satellite to a much bigger quarry at Whitwell in Derbyshire, however it has been mothballed since 2007. The original planning permission states that extraction should cease by the end of October 2017, however a further planning application has been submitted to the County Council seeking a time extension to enable working to continue until 2035. A decision on this application has yet to be made, however if it is approved the quarry would be adequate to cover the majority of the plan period.

Given that sales have been at zero for a number of years, resulting in the 10 year sales average falling significantly, the theoretical landbank in Nottinghamshire is rapidly increasing. As of December 2016 the landbank stood at 668 years. If Nether Langwith was reopened the landbank would start to fall.

There is no evidence to suggest that there is a shortage of crushed rock reserves in Nottinghamshire over the Plan period, however national guidance states that 'Minerals Planning Authorities should plan for a steady and adequate supply of aggregates by 'ensuring that large landbanks bound up in very few sites do not stifle competition'. Based on this guidance it will be important to understand whether or not there is likely to be an unmet demand for crushed rock in Nottinghamshire over the Plan period.

A call for sites will be undertaken as part of the evidence gathering process which will identify new quarries or extensions to existing quarries that the minerals operators wish to be considered for inclusion in the Minerals Local Plan.

(7) Q12 Is there evidence to suggest that additional crushed rock reserves are required to meet demand in Nottinghamshire over the Plan period? If so please provide this evidence.

(7) Q13 Are you aware of any other issues relating to crushed rock provision that should be considered through the Minerals Local Plan review?

Alternative aggregates

It is estimated that alternative aggregates now account for 29% of national consumption of aggregates – a contribution that has risen significantly since the 1980s. This is due to tax incentives, a greater awareness of environmental issues and changes within the construction industry. In Nottinghamshire the biggest sources of alternative aggregates are from some types of construction and demolition waste, ash from coal fired power stations, used railway ballast and desulphogypsum (a synthetic form of gypsum from flue gas desulphurisation plants associated with coal fired power stations).

Alternative aggregates score well in sustainability terms as they utilise materials that would otherwise end up as landfill and reduce the overall need for primary minerals. The new Minerals Local Plan should therefore take a positive approach to their use subject to environmental safeguards.

There are, however, limits on how far alternatives can substitute primary aggregates which is dependent on a range of issues such as availability, cost and the technical specifications required for specific end uses. The British Geological Survey and the Minerals Products Association suggest that the use of recycled and secondary aggregates have almost reached their natural limits.

In the future, some sources of material such as ash from coal fired power stations and desulphogypsum will reduce significantly as the remaining coal fired power stations in Britain are set to close by 2025.

The demand forecasts for primary aggregates set out earlier is additional to the contribution that alternative aggregates make to overall demand as alternative aggregates are already available on the open market.

For the new Minerals Local Plan alternative aggregates are not expected to raise any significant issues over the Plan period. Proposals for recycled aggregates processing facilities are dealt with under the Nottinghamshire and Nottingham replacement Waste Local Plan.

(16) Q14 Are you aware of any issues relating to alternative aggregates that should be considered through the Minerals Local Plan review?

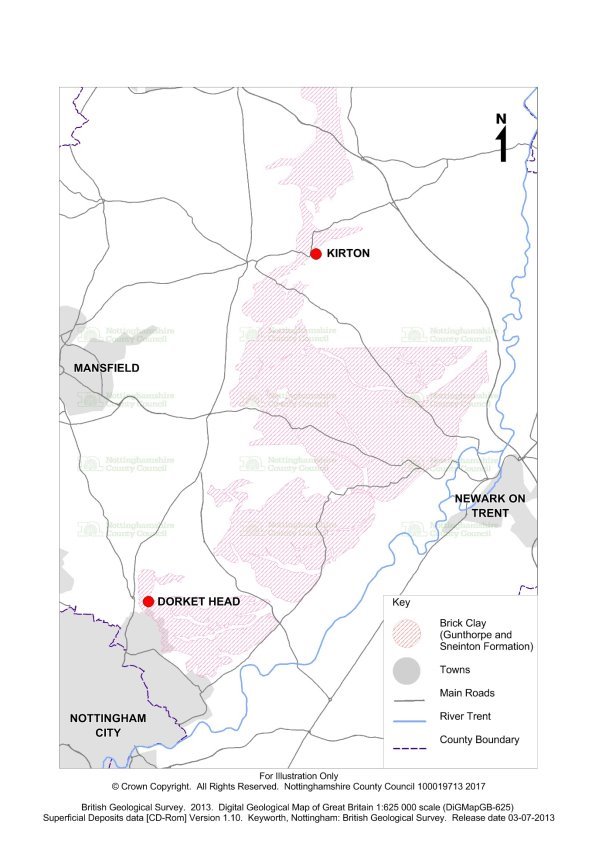

Brick clay provision

There are currently two brickworks and associated clay pits in the County both of which manufacture high quality facing bricks. These are located at Dorket Head near Arnold and Kirton near Ollerton.

Both pits exploit specific clay formations which are exposed along the western edge of the main outcrop (see Plan 4). Nearly all the mineral extracted in Nottinghamshire is red firing clay, but some cream firing clay is also dug at Kirton.

National guidance on brick clay extraction recognises that the high level of investment and ongoing maintenance justifies the provision of a 25 year landbank for individual brick works. Neither clay pit currently has sufficient reserves of clay for the plan period.

Permitted reserves at Dorket Head are expected to be adequate until 2030. A small extension to the south of the existing permitted clay pit could be possible in the future. If this extension is worked there is unlikely to be any further options to extend the existing clay pit.

Kirton clay pit only has adequate reserves until 2019, however a planning application has been submitted to the County Council for a western extension to the existing Kirton clay pit. If this application is granted permission it would secure adequate clay reserves for a further 25 years, well beyond the current Plan period.

The Minerals Local Plan will need to address the issue of how adequate clay reserves are maintained to supply the Dorket Head brick works in the future. Potential options include the identification of a site specific allocation (either in the vicinity of the existing Dorket Head works or a more remote clay pit) or the inclusion of a criteria based policy to ensure supply can be maintained over the plan period whilst ensuring any impacts on the environment or local communities is minimised.

A call for sites will be undertaken as part of the evidence gathering process which will identify new quarries or extensions to existing quarries that the minerals operators wish to be considered for inclusion in the Minerals Local Plan.

New brick works

The Minerals Local Plan will need to consider the possibility of new brick works coming forward, however, at present there are no know proposals.

(8) Q15 Should the Plan identify a specific replacement quarry (remote extension / new site) to Dorket Head clay pit or should a criteria based policy be developed to ensure an adequate supply of clay can be maintained over the plan period?

(9) Q16 Is a criteria based policy the most suitable approach to cover the potential for new brick works and associated clay pits?

Plan 4 Brick Clay resource

Gypsum provision

In Nottinghamshire two distinct gypsum resources are worked. The Marbleagis drift mine at East Leake exploits the 'Tutbury Gypsum' that supplies an associated plasterboard plant and plaster works. Bantycock Quarry near Balderton, Newark exploits the 'Newark Gypsum' which comprises a number of relatively thin seams. The lowest seams are very high quality and are the only mineral of this grade to be found in the UK. It is used in specialist plasters and a wide range of other products ranging from dentistry to food additives. The main plaster products produced in Nottinghamshire supply much of southern and eastern England and the Midlands whilst the specialist products have national and international markets.

Since the mid-1990s national and local gypsum production declined as much of the natural gypsum used in plasterboard was replaced with 'desulphogypsum' (DSG). DSG is a high quality synthetic gypsum produced as a by-product from flue gas desulphurisation plants that have been retrofitted at most coal fired power stations, including all three stations in Nottinghamshire. However this situation is changing as the availability of DSG is rapidly declining as the use of coal as an energy source is falling and the remaining coal fired power stations are due to close by 2025. Going forwards the use of natural gypsum is set to increase, and will have to be sourced from new resources in the UK or from imports.

Permitted reserves at Marbleagis Mine (within Nottinghamshire) should be sufficient until at least 2026.Thereafter the only option is for the mine to extend eastwards towards Wymeswold in Leicestershire. Bantycock Quarry has permitted reserves until 2027 although a scoping request has been submitted to the County Council seeking a time extension to 31st December 2030.

Identifying new reserves is a longer term issue that the Minerals Local Plan will need to address. Land to the south of Bantycock Quarry was allocated in the 2005 Minerals Local Plan and could be a potential option for inclusion in the new Minerals Local Plan to maintain reserves over the plan period.

Other potential options for new gypsum quarries may exist along the outcrop which extends as a belt running to the north and south between East Leake and Newark. (See Plan 2) The need for specific grades of gypsum will dictate the available locations for new quarries to be located.

(10) Q17 Should the plan seek to identify specific site allocations for gypsum provision or should a criteria based policy be developed to ensure an adequate supply of gypsum can be maintained over the Plan period?

(6)

Q18 Are you aware of any

issues regarding the provision of gypsum that should be

considered as part of the Minerals Local Plan review?

Silica Sand provision

Silica sand is a non-aggregate form of Sherwood Sandstone that is also known as 'industrial sand'. One permitted quarry exists in Nottinghamshire at Two Oaks Farm near Kirkby in Ashfield. This quarry produces special sands for a variety of industrial, construction, sporting and equestrian markets. In addition some aggregate sand is also produced. In operational terms the extraction of silica sand is similar to aggregate sand, the main distinction being that much larger and more sophisticated washing and processing plants are required.

No significant issues are expected to be raised over the Plan period to 2036 as reserves at Two Oaks Farm are forecast to last until approximately 2053 which is more than adequate to satisfy the minimum 10 year landbank of permitted reserves as set out in national guidance.

A criteria based policy is considered appropriate to cover any potential future requirements to ensure supply can be maintained over the Plan period whilst ensuring any impacts of the environment or local communities is minimised.

(5) Q19 Are you aware of any issues regarding the provision of Silica Sand that should be considered as part of the Minerals Local Plan review?

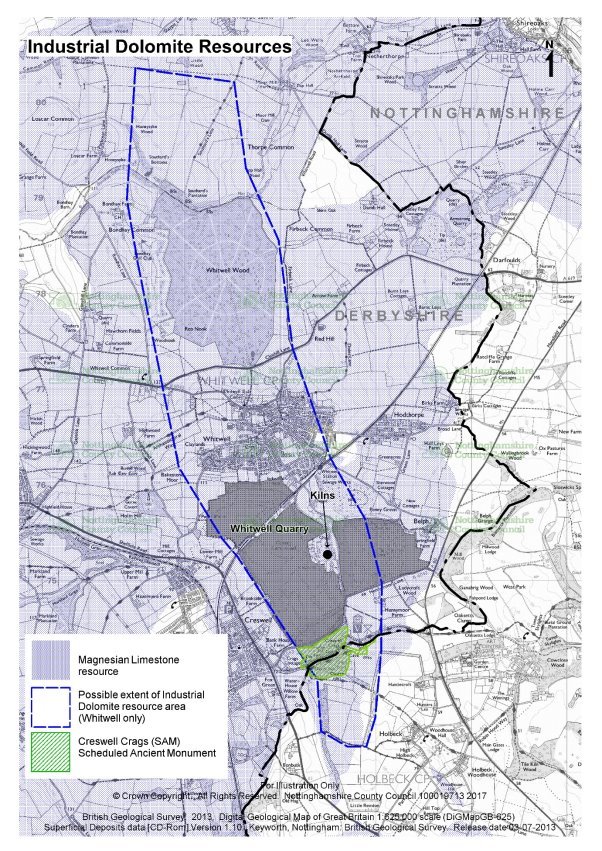

Industrial Dolomite provision

No industrial dolomite is currently worked in Nottinghamshire however a suitable resource is known to exist near Holbeck in the west of the County. This resource lies to the south of a large quarry at Whitwell in Derbyshire where industrial dolomite is quarried alongside aggregate stone on a large scale. (See Plan 5)

Typically around 1 million tonnes are extracted at Whitwell quarry every year with the tonnage being split evenly between the industrial and aggregate mineral. The industrial dolomite feeds two on-site kilns that convert the raw dolomite in to a range of refractory and other products which are exported to 28 countries spanning four continents. The biggest end-user of this product is the iron and steel industry however it is also used in a variety of chemicals, agriculture and glass making.

The international importance of the Whitwell resource reflects the scarcity of this high quality mineral which locally occurs within the Magnesian Limestone resource that is predominantly worked for aggregates. The only other comparable resource in the UK is found in Thrislington, Durham where production is focussed on supplying domestic markets.

Subject to the granting of planning permission for a series of small extensions to the existing quarry (being dealt with by Derbyshire County Council), permitted reserves at Whitwell are likely to be adequate until 2033 for industrial dolomite (and 2040 for aggregate grade limestone). Further options to extend the quarry within Derbyshire are very limited and therefore the resource found in Nottinghamshire could be worked as a satellite extension to the existing Whitwell quarry.

Given the need to blend different grades of dolomite to meet specific customer requirements, any possible quarry in Nottinghamshire would need to be operational before reserves are worked out in Derbyshire.

A number of nationally important designations also occur in the area including the Creswell Crags Scheduled Ancient Monument categorisation, a Site of Special Scientific Interest and the Welbeck Abbey Registered Park and Garden. Creswell Crags is also included on the UK Tentative list of potential sites for World Heritage Nomination. Any proposals would require careful consideration of the potential impacts on the historic environment offset against the international need for the mineral.

(11) Q20 Are you aware of any issues regarding the provision of industrial dolomite that should be considered as part of the Minerals Local Plan review?

Plan 5 Industrial dolomite resource

Building stone provision

The continued quarrying of local building stones play an important role in helping to preserve the historic environment and enhancing the local distinctiveness of an area. Local stone is needed to allow existing historic buildings to be properly repaired and it also means new buildings in historic areas can blend in more effectively.

The only building stone resource currently worked in Nottinghamshire is 'Bulwell Stone', a buff coloured limestone found between Bulwell and Hucknall. It is used as a local building stone and more widely as a walling stone fronting many older properties in Nottingham and its suburbs. Extraction is now limited to Yellowstone Quarry at Linby.

Historically the Bulwell Stone and the Magnesian Limestone were worked much more widely between Nottingham and Mansfield and used on a variety of building projects including Southwell Minster, Ely Cathedral and the lower courses of the Houses of Parliament.

National policy on building stone promotes the conservation and use of the building stone industry and resources to ensure that adequate provision can be made to help conserve the historic built environment and local distinctiveness.

Yellowstone Quarry has estimated reserves of around 120,000 tonnes. At permitted extraction rates this would be adequate until 2035, however the quarry is currently inactive and therefore permitted reserves are likely to last beyond the Plan period.

Based on the above and the fact that no new sites have been put forward in a number of years, there is no evidence to suggest that there will be a shortage of building stone reserves in Nottinghamshire over the Plan period. However over the life of the Plan, demand for a specific building stone could result in the need to develop a new quarry.

It is therefore proposed to develop a criteria based policy approach in the new Minerals Local Plan to cater for any need for specific building stone reserves over the Plan period whilst ensuring any impacts on the environment or local communities is minimised.

(4) Q21 Is there evidence to suggest that additional building stone reserves are required to meet demand in Nottinghamshire over the plan period? If so please provide this evidence.

(4) Q22 Are you aware of any other issues relating to building stone provision that should be considered through the Minerals Local Plan review?

Coal provision

Most of Nottinghamshire's coal resources are deeply buried and have to be exploited by deep mining. It is only in the far west of the County along the Erewash Valley where the coal measures are exposed, that surface (opencast) extraction is possible. The last deep mine in Nottinghamshire located at Thoresby Colliery closed in July 2015. A proposal to work surface mined coal at Shortwood near Cossall has planning permission but has yet to be worked.

Coal recovery

Historical coal processing was often inefficient and substantial quantities of coal were left in the spoil. At some sites it is economic to recover this coal, which can amount to several hundred thousand tonnes in a single large tip. One example of this was Langton Colliery tip located near Kirkby–in-Ashfield that was worked between 2011 and 2013.

Coal pond fines created during the normal processing of coal, can also be used as a fuel at coal fired power stations. The availability of this material is dependent on the availability of suitable colliery lagoons, however it can provide material that would otherwise be wasted. No schemes are currently proposed but may come forward over the life of the plan.

National guidance states that planning permission should not be granted for the extraction of coal unless it can be made environmentally acceptable through planning conditions or if not where local or national benefits outweigh the likely impacts. There are no production targets as the Government believes this is a matter for the markets.

Given that deep mined coal no longer takes place in Nottinghamshire and the only surface mine has yet to be worked, it is not expected that significant issues will be raised for the extraction of virgin coal over the Plan period. There is potential (albeit limited) for the re-working of old colliery spoil tips and colliery lagoons in Nottinghamshire, and so the Minerals Local Plan will need to address this.

A criteria based policy is considered appropriate to cover any potential future requirements for coal provision or the reworking of colliery spoil tips or lagoons.

(6) Q23 Are you aware of any issues relating to coal extraction that should be considered through the Minerals Local Plan review?

Hydrocarbons provision

Hydrocarbon minerals, which comprise oil and gas, are the most important energy minerals produced and consumed in the UK. In2014 UK consumption stood at 131 million tonnes, however 51 million tonnes of this was imported, a figure that has been steadily increasing in recent years. As a result there is a strong impetus to explore and develop new domestic sources of oil and gas.

National guidance says that when planning for on-shore oil and gas development, including unconventional hydrocarbons, Mineral Planning Authorities should include criteria based policies for each of the exploration, appraisal and production phases of hydrocarbon extraction.

Planning permission is one of the main regulatory requirements that operators must meet before drilling a well for both conventional and unconventional hydrocarbons.

The County Council is responsible for granting permission for the location of any wells and well pads, and will impose conditions to ensure that the impact on the land is acceptable. However it is not the only regulatory body that permission for extraction is required from. Others include:

- The Oil and Gas Authority – Issues Petroleum Licences, gives consent to drill under the Licence once other permissions and approvals are in place, and has responsibility for assessing risk of, and monitoring, seismic activity, as well as granting consent to flaring or venting;

- Environment Agency (EA) – protects water resources (including groundwater aquifers), ensures appropriate treatment and disposal of mining waste, emissions to air, and suitable treatment and management of any naturally occurring radioactive materials;

- Health and Safety Executive (HSE) – regulates the safety aspects of all phases of extraction, in particular responsibility for ensuring the appropriate design and construction of a well casing for any borehole.

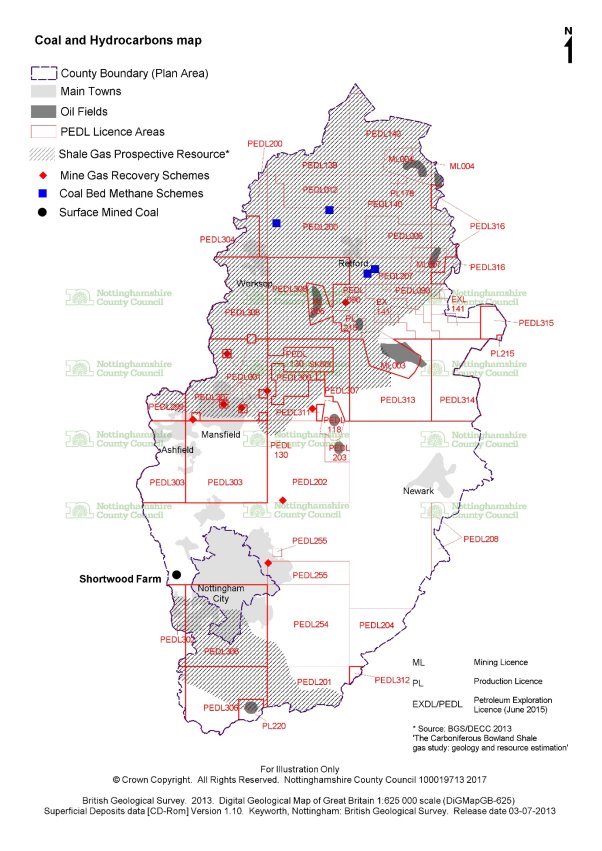

Historically two main forms of hydrocarbons have been worked in Nottinghamshire; oil and mine gas. However other unconventional hydrocarbons such as coal bed methane and shale gas extraction are being developed and could be worked over the Plan period. Plan 6 identifies the hydrocarbon resources and sites in Nottinghamshire. The key issues for each hydrocarbon type are set out below.

Oil

Oil has been extracted on a small scale since the Second World War when oil reservoirs in deeply buried sandstones were identified at Eakring. Since then further oil fields have been identified mostly in north Nottinghamshire but ranging as far south as Rempstone near the boundary with Leicestershire.

The oil recovered in Nottinghamshire is of high quality, and mainly used in the plastics and chemical industries, rather than as a fuel. The majority of oil is taken by rail from the central collecting station at Gainsborough to refineries at Immingham, in North East Lincolnshire.

Oil exploration and production has raised few concerns and it is not expected to raise any critical issues for the new Minerals Local Plan to resolve.

Mine gas

Coal seams exposed during deep mining release methane trapped within them. This methane also known as 'mine gas', is a major mining hazard. Once mining and ventilation ceases methane can fill the mineshafts and other voids and escape to the surface where it can pose a threat to health and safety in the locality. The situation has become much more prevalent recently because of the number of collieries that have closed over the last 30 years.

Mine gas can be recovered and burnt to generate electricity, an activity that is very sustainable in that it reduces the escape of one of the most potent 'greenhouse gases' into the atmosphere and converts it into a useful fuel. This in turn reduces the demand for other finite fossil fuels.

Coal bed methane

Coal bed methane extraction involves removing methane directly from the coal seam without actually mining the coal. This industry is most developed in the USA, whilst in the UK and Europe it remains in its infancy. Interest in this industry is developing and it could become a significant energy source for the future. In Nottinghamshire a number of proposals for the exploration and development of coal bed methane have been permitted but have not yet been developed. Nearly all of Nottinghamshire overlies a potential coal bed methane resource but the most promising prospects are believed to exist in the eastern half of the County.

The environmental impacts of coal bed methane extraction are similar to on-shore oil although the wells may be more numerous and closely spread. Water pollution is a potential issue as water pumped out of the coal seams can be very saline and therefore needs careful disposal.

As the future economic interest in this mineral is very uncertain it is unknown if it will raise any critical issues for the new Minerals Local Plan.

Shale gas

Vast quantities of methane exist in many shale deposits worldwide and recent technological advances have now made it economically possible to exploit them.

Shale gas extraction involves vertical and horizontal drilling to reach the deeply buried shale rock layer. A mixture of water and sand is then pumped under high pressure into the bore hole to fracture the rock (a process known as 'fracking'). The gas trapped in the rock is then released and can be collected.

Like coal bed methane extraction, this technology is most developed in the USA where it has seen a period of very rapid development and is now exploited on a large scale. The UK also has a significant, but as yet largely untested, potential shale gas resource. In Nottinghamshire potential shale gas resources are thought to exist in deeply buried shale deposits that exist below much of the south and north areas of the County. Three exploration wells have been granted planning permission in the north of the County but to date no further planning applications for appraisal or extraction have been submitted.

Further information regarding shale gas development can be found in the planning and environment section of the County Council website: http://www.nottinghamshire.gov.uk/planning-and-environment/shale-gas-development

A criteria based policy for hydrocarbons ensuring that a proposed development does not have any unacceptable impacts on the environment or residential amenity at each phase (exploration, appraisal, extraction) is considered appropriate to address future conventional and unconventional hydrocarbon development in Nottinghamshire.

(28) Q24 Are you aware of any issues relating to hydrocarbon extraction that should be considered through the Minerals Local Plan review?

Plan 6 Coal and hydrocarbons in Nottinghamshire