Nottinghamshire Minerals Local Plan Publication Version

4. Minerals Provision Policies

Introduction

4.1. As explained in Chapter 3, minerals resources are very important to the County and a steady and adequate supply of minerals to meet future needs has to be planned for. Strategic policy SP4 sets the overall context for future mineral provision whilst the minerals provision policies set out within this chapter identify how and where these needs will be met for the different types of aggregate, industrial and energy minerals.

4.2. In most cases, existing sites which have not yet been worked out will meet some of this demand but the policies show where additional provision will be needed to make up any expected shortfall. Where a shortfall is identified, this will be met from a combination of new and/or extended sites although the priority is to extend existing sites wherever possible in line with strategic objective (SO1) to improve the sustainability of minerals development.

4.3. In order to identify the range of sites that could be available for mineral extraction over the plan period the council has worked with the minerals industry and local landowners to understand the location of workable mineral resources across the County. In response to a 'call for sites' exercise, mineral operators and landowners submitted a range of sites for which there were inferred minerals resources. This included both new sites and extensions to existing sites.

4.4. These sites have been carefully assessed to decide which are the most suitable and realistic options to allocate in the Plan. The sites which are allocated are shown in Policies MP2-12. The justification text following each policy includes more detail about each site and how they relate to any existing permitted site. Full details of the site assessment process is set out in the Site Selection Methodology and Assessment document.

4.5. All of the sites will be subject to site allocation development briefs which will deal with site specific issues, including how the sites should be restored. These individual site development briefs are included in Appendix 2.

MP1: Aggregate Provision

Introduction

4.6. Aggregates make a significant contribution to the construction industry, accounting for around 90% of the materials used. In England alone, nearly a quarter of a billion tonnes are consumed every year. Sustaining this level of demand is of national concern and raises major planning and environmental issues. All mineral planning authorities are required to plan for a certain proportion of the national demand for all aggregate minerals, known as the local apportionment, and to maintain a certain level of permitted reserves, known as the landbank.

4.7. Nottinghamshire has historically been a significant producer of sand and gravel the East Midlands, most of which comes from the Trent and Idle Valleys. This river or 'alluvial' mineral is mainly used in the production of concrete. Building and asphalting sand is produced from the Sherwood Sandstone resource but in much smaller quantities. Nottinghamshire's limestone production is relatively small, accounting for just 0.1% of the regional output, reflecting the County's limited resource of this mineral.

(11) Policy MP1: Aggregate Provision

-

To meet identified levels of demand for aggregate mineral over the plan period (2018-2036) the following provision will be made:

- 32.30 million tonnes of Sand and Gravel

- 7.03 million tonnes of Sherwood Sandstone

- 0.09 million tonnes of crushed rock

- The County Council will make provision for the maintenance of landbanks of at least 7 years for sand and gravel, 7 years for Sherwood Sandstone and 10 years for crushed rock, whilst maintaining a steady and adequate supply over the plan period.

- Proposals for aggregate extraction outside those areas identified in policies MP2, MP3 and MP4 will be supported where a need can be demonstrated.

Justification

4.8. The National Planning Policy Framework requires MPAs to produce a Local Aggregates Assessment (LAA) on an annual basis. This assesses both the demand for and supply of aggregates based on the average of the last 10 and 3 year sales data. This takes into account all possible supply options including the availability or otherwise of secondary or recycled aggregates as well as land-won sources. It also takes account of any significant local infrastructure projects that are taking place, or planned, and any opportunities or constraints that might influence future aggregate production.

4.9. MPAs are also required to work with other local Mineral Planning Authorities through an Aggregate Working Party to ensure that the approaches taken remain consistent and adequate supply is maintained. Nottinghamshire is part of the East Midlands Aggregate Working Party.

4.10. Based on the findings of the Local Aggregates Assessment published in October 2017 (December 2016 data) demand over the plan period has been calculated. For this exercise the plan period covers a 19 year period from 2018-2036. Tables 1 and 2 set out the production figures and demand over the plan period.

Table 1 Annual aggregate production (million tonnes)

|

|

2007 |

2008 |

2009 |

2010 |

2011 |

2012 |

2013 |

2014 |

2015 |

2016 |

|

Sand and gravel |

2.97 |

2.37 |

4.27 |

4.56 |

4.71 |

4.55 |

4.39 |

4.43 |

4.52 |

4.27 |

|

Sherwood Sandstone |

0.55 |

0.46 |

0.32 |

0.32 |

0.35 |

0.36 |

0.34 |

0.34 |

0.38 |

0.32 |

|

Crushed rock |

0.03 |

0.02 |

0.00 |

0.00 |

0.00 |

0.00 |

0.00 |

0.00 |

0.00 |

0.00 |

Table 2 LAA Average Production Figure and Estimated Total Aggregate Demand (million tonnes)

|

LAA derived annual production figure |

Estimated demand 2018-2036 (19 years) |

|

|

Sand and gravel |

4.7 |

32.3 |

|

Sherwood Sandstone |

0.37 |

7.03 |

|

Crushed rock |

0.005 |

0.095 |

4.11. Some of the estimated demand shown in Table 2 above, can be met from remaining permitted reserves (i.e. the mineral that is left in existing quarries that can still be worked). However, for most minerals, this will not be sufficient to cover the whole of the plan period and additional reserves will need to be permitted in order to make up the shortfall.

4.12. For each of the minerals (sand and gravel, Sherwood Sandstone and crushed rock) the shortfall has been calculated by deducting the estimated level of permitted reserves from the total amount of aggregate required over the life of the Plan. However it is important to remember that the level of permitted reserves can change over time as minerals operators re-assess the available reserves at each site. The level of remaining reserves will also be affected by any change in the annual output from each site. This highlights the importance of annual monitoring as set out in Chapter 6.

4.13. One of the most important indicators for aggregates is to assess how long the current stock of permitted reserves is likely to last. This is known as the 'landbank'. All MPAs are required to maintain a landbank of at least seven years' worth of sand and gravel reserves and ten years' worth of crushed rock reserves. The average production figures set out in the LAA will be compared against the permitted reserves of aggregates to monitor the level of the landbanks. If permitted reserves fall significantly below the required amount this could trigger a review of this section of the plan. Further information is available in the monitoring chapter.

4.14. The specific provision policies MP2 – MP4, below, show how the Plan will meet the anticipated shortfalls for each aggregate mineral and how the proposed sites have been selected

MP2: Sand and Gravel Provision

Introduction

4.15. In geological terms the sand and gravel resource is extensive, located in the Trent and Idle River valleys. Within the Trent Valley, production has historically been concentrated around Nottingham and Newark. This pattern has developed at least in part in response to a need to be close to the main markets for the mineral (due to sand and gravel being a low cost bulk material, meaning that haulage is a significant element of its cost). Currently between a third to a half of the County's production supplies markets in Yorkshire and Humberside, which the Idle Valley is well placed to serve.

(19) Policy MP2: Sand and Gravel Provision

-

An adequate supply of sand and gravel will be identified to meet expected demand over the plan period from:

-

The extraction of remaining reserves at the following permitted quarries:

(Million tonnes)

MP2a Newington South 0.39mt

MP2b Finningley 0.45mt

MP2c Sturton Le Steeple 7.50mt

MP2d Bawtry Road 0.60mt

MP2e Cromwell 2.40mt

MP2f Besthorpe 0.50mt

MP2g Girton 3.56mt

MP2h Langford Lowfields 4.95mt

MP2i East Leake 2.34mt

MP2j Scrooby South 0.62mt

-

The following extensions to existing permitted quarries:

MP2k Bawtry Road West 0.18mt

MP2l Scrooby Thompson Land 0.06mt

MP2m Scrooby North 0.56mt* (0.62mt)

MP2n Langford Lowfields North 4.70mt* (8.00mt)

MP2o Besthorpe East 3.30mt

-

New sand and gravel quarries:

MP2p Mill Hill nr Barton in Fabis 3.0mt**

Note: The above sites are shown on the Policies Map

Proposals to extract specialist grey sand reserves will be supported where a need can be demonstrated.

Planning applications for site allocations should be made in accordance with the site development briefs set out in Appendix 2

* Available within the plan period (total estimated reserves in brackets).

**Excludes potential reserves within the Nottingham City administrative area.

-

The extraction of remaining reserves at the following permitted quarries:

Justification

4.16. Based on the average production figures set out in the aggregate provision policy MP1, the plan needs to provide an estimated 32.3 million tonnes of sand and gravel over the plan period (see Table 2).

4.17. As of December 2016, permitted sand and gravel sites reserves (MP2a-j) located in the county stood at 17.5 million tonnes. Whilst these sites will initially help to maintain a seven year landbank and ensure continuity of supplies, there is a need to secure additional reserves over the Plan period.

4.18. The estimated sand and gravel shortfall over the plan period will therefore be 14.8 million tonnes of sand and gravel up to 2036.

4.19. Planning permission was granted to extend Langford Lowfields quarry (south and west) in 2018, increasing the level of permitted reserves by 3.6 million tonnes. This has extended the life of the existing permitted Langford Lowfields quarry which will continue to provide sand and gravel over the plan period.

4.20. As a result Policy MP2, allocates 5 extensions to existing quarries (MP2k-o) and 1 new quarry (MP2p) which total 11.8 million tonnes.

4.21. Table 3 below sets out a summary of the site allocations and how each is expected to contribute towards the sand and gravel shortfall over the plan period. A delivery schedule, which looks at how each of the extensions and new site will contribute to the shortfall, can also be found in appendix 4.

4.22. Given that sand and gravel can only be worked where it is found, a geographical spread of sites has been identified to enable the continued supply of sand and gravel to the different market areas to minimise the wider impacts of HGV transport.

Table 3 Contributions to the sand and gravel shortfall over the plan period

|

Site |

Location |

Reserves (million tonnes) |

Operational period (inclusive) |

|

Extensions |

|||

|

MP2k Bawtry Road west |

Idle Valley |

0.18 |

2026-2031 |

|

MP2l Scrooby, Thompson Land |

Idle Valley |

0.06 |

2019-2029 |

|

MP2m Scrooby North |

Idle Valley |

0.56* |

2023- beyond plan period |

|

MP2n Langford Lowfields north |

Newark |

4.70* |

2026 - beyond plan period |

|

MP2o Besthopre East |

Newark |

3.30 |

2020 – 2036 |

|

New site |

|||

|

MP2p Mill Hill nr Barton In Fabis |

Nottingham |

3.0** |

2019-2030 |

|

Total |

|

11.8 |

|

*available within the plan period

** Excludes potential reserves within the Nottingham City administrative area

Misson Grey Sand

4.23. Deposits of grey building sand occur erratically in the Misson area, sometimes below the main sand and gravel resource and sometimes at the surface. Historically, this grey sand has been worked on a relatively small scale. This sand is used as grey mortar sand, which has a premium value because most local mortar sands are red and yellow being derived from the Sherwood Sandstone.

4.24. Although counted as sand and gravel in planning and landbank terms, it would be inappropriate to treat it as part of the normal sand and gravel resource when assessing 'need'. This is because the grey sand serves a particular niche market which alluvial sand and gravel cannot meet. It is therefore reasonable to allow continued production of this sand, irrespective of the prevailing Countywide sand and gravel landbank.

Site Information

Existing Permitted Quarries and proposed Extensions- Idle Valley

Newington South (MP2a)

4.25. This existing permitted site is located 2km south west of Misson Village and 3.5km north east of Bawtry. The quarry has permitted reserves which are expected to last until the end of 2019. A planning application is currently being considered which involves extracting sand and gravel from a previously unworked part of the existing permitted quarry. If granted permission this will extend the life until the end of 2022. The existing quarry is currently being restored to low lying wetland. (See appendix 3 – inset 2)

Finningley (MP2b)

4.26. The existing permitted quarry is located to the south east of Finningley village and crosses the border between Nottinghamshire and Doncaster Metropolitan Borough Council (MBC). The quarry has permitted reserves until the end of 2019. No further extensions to the quarry are considered possible. (See appendix 3 – inset 1)

Sturton Le Steeple (MP2c)

4.27. The existing permitted area is located to the east of Sturton Le Steeple village, approximately 9km south of Gainsborough. The quarry has planning permission but extraction has yet to fully commence. The quarry has planning permission to extract 500,000 tonnes per annum over a 20 year period, however the operator states that anuual output is likely to be 100,000 tonnes per annum. The quarry will be restored to a combination of nature conservation including wetland, agriculture and forestry. (See appendix 3 – inset 4)

Bawtry Road (MP2d)

4.28. The existing permitted quarry is located between Misson to the east and Newington to the south. The quarry is expected to have sufficient permitted reserves until 2026. The quarry will be restored to agricultural land.

4.29. The western extension to the quarry (MP2k) is expected to be worked once existing reserves have been worked in 2026. Output will remain in line with the existing permitted quarry at approximately 30,000 tonnes per annum and will continue to use existing plant site and access. Reserves are expected to last approximately 6 years. (See appendix 3 – inset 2)

Scrooby

4.30. Extraction has taken place at Scrooby since the 1930s, working both sand and gravel and Sherwood Sandstone (see policy MP3 for Sherwood Sandstone). An existing permitted Sand and gravel quarry (MP2j) has sufficient reserves until 2023. The existing processing plant remains in use.

4.31. Two extensions to this quarry are allocated. Both would utilise the existing processing plant and site access.

4.32. The Scrooby Thompson Land (MP2l) is expected to be worked in 2020 and 2021. The quarry would be worked at a rate of approximately 40,000 tonnes in 2020 and 20,000 tonnes in 2021.

4.33. The Scrooby north quarry (MP2m) will be worked from 2023 at an approximate output of 40,000 tonnes per annum. (See appendix 3 – inset 3)

Existing Permitted Quarries and Proposed Extensions- Newark Area

Cromwell Quarry (MP2e)

4.34. The existing quarry is located to the north-east of Cromwell village alongside the A1, nine kilometres north of Newark and is currently being worked. Due to the quarry's location close to the A1, mineral can be transported to northern or southern markets.

Besthorpe Quarry (MP2f)

4.35. The existing quarry is located to the north west of Besthorpe village near Newark. The quarry has sufficient permitted reserves until the end of 2020. Output at the quarry is approximately 150-200,000 tonnes per annum. Historically a proportion of the sand and gravel produced at the quarry was barged up the river to the Europort at Wakefield. However this has not taken place for a number of years. The site is predominantly being restored to wetland habitats and is being managed by Nottinghamshire Wildlife Trust. (see appendix 3 - Inset 8)

4.36. The eastern extension to the quarry (MP2o) is expected to be worked once existing reserves have been extracted. Output will remain in line with the existing permitted quarry and will use the existing plant site. Estimated reserves total 3.3mt and are expected to last 16 years.

Girton Quarry (MP2g)

4.37. The existing quarry is located 8km north of North Collingham and 16km from Newark. The quarry is currently 'mothballed' but has permission until 2036. Sand and gravel is being worked from existing stockpiles at around 50,000 tonnes per annum but this is expected to increase to 100,000 in approximately 2020 when the quarry is expected to re-open. The quarry will be restored back to agriculture and wetland conservation. (See appendix 3 – inset 7)

Langford Lowfields Quarry (MP2h)

4.38. The existing quarry is located between Langford and Collingham, north of Newark. Planned output at the quarry is approximately 450,000 tonnes per annum. The quarry is being reclaimed to a major wildfowl/wetland reserve which is being managed by the RSPB. Planning permission was granted in 2018 for a southern and western extension extending the life the quarry until 2026.

4.39. The northern extension to the quarry (MP2n) covers 124 Ha and is expected to be worked once existing reserves have been extracted in 2026. Output will remain in line with the existing permitted quarry and will use the existing plant site. Reserves are expected to last beyond the plan period.

Existing Permitted Quarries and Proposed Extensions- Nottingham Area

East Leake Quarry (MP2i)

4.40. The existing permitted quarry is located 1km to the south of East Leake. The quarry has sufficient permitted reserves until the end of 2026 at an output of 180,000 tonnes per annum. The quarry is being restored to agriculture and nature conservation. One extension to the site is allocated which would utilise the existing processing plant and site access.

New greenfield quarry - Nottingham area

Mill Hill near Barton In Fabis (MP2p)

4.41. This allocation is for a new greenfield site that is located 6km west of Nottingham. Output from the site would be approximately 280,000 tonnes per annum. The site is expected to be operational in approximately 2019 and would be worked over a 12-15 year period. The quarry would be restored using a range of habitats including floodplain grazing marsh, reed bed, low land grassland and agricultural land. The draft allocation area contains approximately 3 million tonnes of reserves, however a planning application for a larger site that also covers an area within the Nottingham City administrative area has been received by both the County and City Councils and is currently being determined. (appendix 3 – inset 16).

MP3: Sherwood Sandstone Provision

Introduction

4.42. Sherwood Sandstone is a specialist form of sand and gravel that is used primarily as asphalt and mortar sand. It accounts for around a sixth of the County's sand and gravel production. The Sherwood Sandstone resource covers nearly a quarter of the County, occurring as a broad belt between Nottingham and South Yorkshire. This is also a major aquifer and serves as an important water source for a wide area. Different grades and colours of sands (which have varying end uses) are found in the resource, however there is no comprehensive geological information about how these are distributed.

(1) Policy MP3: Sherwood Sandstone Provision

An adequate supply of Sherwood Sandstone will be identified to meet expected demand over the plan period from:

-

The extraction of remaining reserves at the following permitted quarries:

(Million tonnes)

MP3a Burntstump 4.88mt

MP3b Bestwood 2 2.74mt

MP3c Scrooby Top 0.60mt

-

The following extensions to existing quarries.

MP3d Bestwood 2 North 0.75mt

MP3e Scrooby Top North 4.68mt* (4.83mt)

Note: The above sites are shown on the Policies Map

Planning applications for site allocations should be made in accordance with the site development briefs set out in Appendix 2

* Available within the plan period (total estimated reserves in brackets).

Justification

4.43. Based on the Sherwood Sandstone requirement set out in the aggregate provision policy (MP1), the plan needs to provide 7.03 million tonnes of Sherwood Sandstone over the plan period.

4.44. As of December 2016 there were 4 permitted Sherwood Sandstone sites which contained estimated reserves of 3.85 million tonnes. Whilst these sites will help to maintain a seven year landbank and ensure continuity of supplies, there is a need to secure additional reserves over the plan period.

4.45. Using the annual production figure included in Table 1 and the estimated Sherwood Sandstone reserves from 2016, the plan would need to provide an additional 3.3 million tonnes of Sherwood Sandstone up to 2036.

4.46. The plan will therefore have to allocate further reserves to make up the expected shortfall in provision. Policy MP3 therefore identifies proposed extensions at three existing sites as discussed below. The delivery schedule, in Appendix 1 shows how these extensions are expected to contribute towards the shortfall.

4.47. Planning permission was granted to extend Bestwood 2 quarry (eastern extension) in 2018 which increased permitted reserves by 4.44 million tonnes. This has extended the life of the existing Bestwood 2 quarry which will continue to provide Sherwood Sandstone over the plan period.

4.48. As a result Policy MP3, allocates 2 extensions to existing quarries (MP3d-e) which total 2.43 million tonnes.

4.49. Table 4 below sets out a summary of the site allocations and how each is expected to contribute towards the Sherwood Sandstone shortfall over the plan period. A delivery schedule, which looks at how each of the extensions and new site will contribute to the shortfall, can also be found in appendix 4.

Table 4 Contributions to the Sherwood Sandstone shortfall over the plan period

|

Site |

Reserves (million tonnes) |

Operational period (inclusive) |

|

MP3d Bestwood 2 North |

0.75 |

2029-2035 |

|

MP3e Scrooby Top North |

4.68* |

2022 - beyond plan period |

|

Total |

2.43 |

*available within the plan period

Site Information

Burnt Stump (MP3a)

4.50. This existing quarry is located 3.5km west of Calverton. The quarry has planning permission until the end of 2021, although given the high level of permitted reserves the operator may apply for an extension of time in the future. Restoration will be to agriculture and woodland. (See appendix 3 – inset 13).

Bestwood 2 (MP3b)

4.51. This existing permitted quarry is located 1 mile south of Ravenshead and 6 miles south of Mansfield. The existing quarry has a planned output of 140,000 tonnes per annum and is due to be worked out by 2029. The site restoration will include heathland, marshland and sandstone cliff habitats.

4.52. A northern extension is allocated (MP3d). The allocation will be commenced once the existing permitted quarry has been worked out in 2029. Output will remain at 140,000 tonnes per annum for approximately 6 years. The existing processing plant and access will be used. (see appendix 3 – inset 12)

Scrooby Top (MP3c)

4.53. Extraction has taken place at Scrooby since the 1930s working both sand and gravel and Sherwood Sandstone (see policy MP2 for sand and gravel). Extraction at this site is expected to be adequate until 2022.

4.54. A northern extension is allocated (MP3e) The allocation covers 25 ha and will be commenced once the existing permitted reserves are worked out. Output is planned at 120,000 tonnes per annum for 40 years and will utilise the existing processing plant and access. (See appendix 3 – inset 3).

MP4: Crushed Rock (Limestone) Provision

Introduction

4.55. Around 60 million tonnes of limestone are extracted in Great Britain every year making it the largest mineral extractive industry in the Country[1]. The majority of this is used as an aggregate, the remainder being used in the cement, chemical, glass, iron and steel industries and agriculture. Limestone is also an important source of building and ornamental stone.

4.56. Although the East Midlands is one of the most important limestone producing areas, Nottinghamshire's resources are relatively limited and the only permitted reserves are at Nether Langwith Quarry (currently dormant). Limestone is the only 'hard rock' of any economic interest to be found in the County and by regional standards output is very low.

(1) Policy MP4: Crushed Rock (limestone) Provision

An adequate supply of limestone will be identified to meet expected demand over the plan period from the extraction of remaining reserves at the following permitted site:

(Million tonnes)

MP4a Nether Langwith 3.34mt

Note: The above site is shown on the Policies Map

Justification

4.57. Based on the limestone requirements set out in the aggregate provision policy (MP1), the plan does not need to provide any further limestone as current permitted reserves at Nether Langwith quarry (see appendix 3 – inset 5) are adequate to cover the plan period. The quarry has planning permission until 2035 at a planned output of 250,000 tonnes per annum, however actual output has been much lower and it has not been worked for a number of years. At this point it would provide the opportunity to review the restoration scheme to ensure it is in-line with policy SP2 Biodiversity-Led Restoration.

MP5: Secondary and Recycled Aggregates

Introduction

4.58. The terms 'recycled' and 'secondary' aggregate are often used interchangeably. The term 'recycled aggregates' refers to aggregates that have been used previously in construction. Recycled aggregates can comprise construction and demolition wastes, asphalt road planings and used railway ballast.

4.59. 'Secondary aggregates' are by-products of other processes and will not have been used previously as aggregates. They include colliery spoil, china clay waste, slate waste, power station ashes, blast furnace and steel slags, incinerator ashes and foundry sands.

(2) Policy MP5: Secondary and Recycled Aggregates

Development proposals which will increase the supply of secondary and/or recycled aggregates will be supported where it can be demonstrated that there are no significant environmental, transport or other unacceptable impacts.

Justification

4.60. Government policy continues to encourage the use of secondary and recycled materials in construction in order to reduce the need for material from traditional sources. There are substantial amounts of these materials that could contribute further to aggregate supply. In order to conserve natural resources, aggregates (and products manufactured from aggregates) should be recycled wherever possible.

4.61. Although, there is considerable potential for using certain waste materials as secondary aggregates, large quantities either remain on site or end up in landfill. Making greater use of by-products and other waste materials will therefore also help to meet the Government's aim of reducing waste disposal to landfill. The Nottinghamshire and Nottingham Replacement Waste Local Plan sets out strategic policies to promote both temporary and permanent facilities for aggregates recycling facilities.

4.62. Where recycled materials are technically, economically and environmentally acceptable as substitutes for primary materials, then they should be used. It is accepted, however, that there may be problems associated with the ability of these materials to meet required British Standard specifications and that their availability or location might make their use disadvantageous in economic terms.

4.63. It is recognised that many of the adverse environmental effects resulting from the extraction of primary aggregates apply to the use of secondary materials. This is because the processes are similar involving the generation of noise, dust and visual intrusion, and road transport using heavy goods vehicles. Incorporating recycling and secondary aggregate operations into an existing mineral development could also increase the overall harmful effect that the site has on the amenity of the surrounding area, or could increase the life of the development beyond that which is considered acceptable.

MP6: Brick Clay Provision

Introduction

4.64. Brick clay refers to the clay and shale used in the manufacture of building and construction materials. In Nottinghamshire the clay extracted is used for facing bricks, pavers, roofing tiles and clay pipes, although nationally other important uses include cement production.

4.65. Extraction currently only takes place from the Mercia Mudstone resource to the east and south of the County. Resources do exist within the smaller Edlington Formation and Coal measures to the west of the County, however these have not been worked since the 1970s. No detailed assessment has been completed regarding the areas of the Mercia Mudstone which are best suited to brick manufacture; however the 'Gunthorpe Formation' location close to both of Nottinghamshire's existing brick works has been identified by the current operators as particularly suitable.

(2) Policy MP6: Brick Clay Provision

-

An adequate supply of brick clay will be identified to meet expected demand over the plan period and enable a 25 year landbank per brick works to be maintained from:

-

The extraction of remaining reserves at the following permitted sites:

MP6a Kirton

MP6b Dorket Head

-

The extraction of remaining reserves at the following permitted sites:

Note: The above sites are shown on the Policies Map

- Proposals for clay extraction outside the sites identified above will be supported where it can be demonstrated that there are insufficient reserves available to meet the 25 year landbank requirement per site and that the identified sites are not deliverable.

Planning applications for site allocations should be made in accordance with the site development briefs set out in Appendix 2

Justification

4.66. There is no national demand forecast or local apportionment for brick clay although the National Planning Policy Framework (NPPF) does require a 25 year landbank of permitted brick clay reserves to be identified for each brick works. In Nottinghamshire there are two brick works with associated clay pits operated by two national producers – Dorket Head near Arnold and Kirton near Ollerton. Each site is discussed below.

Site Information

Kirton (MP6a)

4.67. The existing brick pit is located to the east of Kirton village, 3km from New Ollerton and provides both red-firing and cream-firing clays directly to the brick works adjacent. The red-firing clay accounts for about 90% of demand. Reserves of red-firing clay are expected to be adequate until 2044. Reserves of cream- firing clay are located to the east of the brick works within a separate working area and are expected to be sufficient until at least 2030. The existing pits are being restored to agricultural land at a lower ground level. A small proportion of clay is imported from Waingroves quarry in Derbyshire for use as a blending material. (Appendix 3 – inset 6)

Dorket Head (MP6b)

4.68. The existing brick pit is located to the north of Arnold, ten kilometres from Nottingham. Clay from the pit is supplied directly to the brick works adjacent with permitted reserves expected to be sufficient until 2033. Part of the site is being restored to agricultural land through a landfill scheme whilst the remainder of the site will be restored to agricultural land and woodland at a lower ground level (see appendix 3 – inset 14).

New brick works and clay pits

4.69. Any applications for new brick works and clay pits would need to have regard to the Strategic and Development Management policies of the plan, but more particularly be considered in light of the need for the development and any potential environmental, social or economic impacts.

MP7: Gypsum Provision

Introduction

4.70. In Nottinghamshire two distinct gypsum resources are worked. The Marblaegis Mine at East Leake exploits the 'Tutbury Gypsum' and supplies an associated plasterboard plant and plaster works. Bantycock Quarry near Balderton, Newark exploits the 'Newark Gypsum'. The lowest seams at this site are very high quality and are the only mineral of this grade to be found in the UK. It is used in specialist plasters and a wide range of other products ranging from dentistry to food additives.

4.71. Since the mid-1990s national and local gypsum production has declined due to increased supplies of desulphogypsum (DSG), a by-product of flue gas desulphurisation plants that have been retrofitted at most coal fired power stations, including all three power stations in Nottinghamshire. The long term future of desulphogypsum is uncertain as new emission controls due in the 2020s could see more coal fired power stations close or switch to other fuels. This is likely to increase the demand for natural gypsum.

(3) Policy MP7: Gypsum Provision

-

An adequate supply of Gypsum will be identified to meet demand over the plan period from:

-

The extraction of remaining reserves at the following permitted sites:

MP7a Marblaegis Mine

MP7b Bantycock Quarry

-

The following extension to the existing Bantycock quarry:

MP7c Bantycock Quarry South 8.5 million tonnes

-

The extraction of remaining reserves at the following permitted sites:

Note: The above sites are shown on the Policies Map

- Proposals for gypsum extraction outside the permitted sites identified above will be supported where a need can be demonstrated.

Planning applications for site allocations should be made in accordance with the site development briefs set out in Appendix 2

Justification

4.72. There is no national demand forecast or requirement to identify a local apportionment figure for Gypsum production and it is up to the industry to identify adequate reserves to maintain production.

Site Information

4.73. Permitted reserves at the Marblaegis Mine (MP7a) are sufficient until at least 2026 and represent the full extent of the mine within Nottinghamshire. (See appendix 3 – inset 17). When these reserves are utilised, mining will move eastwards towards Wymeswold in Leicestershire.

4.74. Permitted reserves at Bantycock Quarry are currently expected to be adequate until around 2023 at current rates of extraction. (See appendix 3 – inset 15)

Bantycock Quarry South (MP7c)

4.75. A southern extension to the existing quarry is being proposed for allocation which would be worked once the existing permitted quarry has been exhausted. Output is expected to be between 350,000 – 500,000 tonnes per annum giving the quarry an additional 15-24 years. The restoration of the quarry is proposed to be largely back to agriculture in line with the existing quarry restoration.

MP8: Silica Sand Provision

Introduction

4.76. Silica sand is a non-aggregate form of Sherwood Sandstone that is also known as 'industrial sand'. Unlike aggregate sands, which are used for their physical properties alone, silica sands are valued for a combination of chemical and physical properties. It is used in the making of glass and creating molds and castings in industrial processing. This sand is also used in sand blasting, adding texture to slick roads and as a raw material in production of ceramics and sports surfaces. Compared to aggregate sand, silica sand resources are much less widespread. In Nottinghamshire silica sand is found within the 'Nottingham Castle Formation'.

4.77. The specialist nature of silica sand products means that the market area is very large and serves local, regional and national requirements. Due to the relatively small volumes of material and the varied destinations all silica sand extracted in Nottinghamshire is currently transported by road.

(1) Policy MP8: Silica Sand Provision

-

The extraction of remaining reserves at the following permitted sites will be utilised to contribute towards the provision of an adequate and steady supply of silica sand sufficient for at least ten years:

MP8a Two Oaks Farm

Note: The above sites are shown on the Policies Map

- Proposals for silica sand extraction outside the sites identified above will be supported where a need can be demonstrated.

Justification

4.78. There is no national demand forecast or local apportionment for silica sand although the NPPF does require a 10 year landbank of permitted reserves to be identified.

4.79. A silica sand quarry at Two Oaks Farm (see appendix 3 – inset 11), south of Mansfield has permitted reserves of approximately 12 million tonnes which is expected to be adequate for around 40 years. This satisfies the recommended 10 year landbank per quarry (or 15 years when significant new capital is needed) set out in national policy.

MP9: Industrial Dolomite Provision

Introduction

4.80. Industrial dolomite is an industrial grade limestone that is mainly used in the iron and steel industry. The resource in the UK is rare and locally is only found in parts of the Magnesian Limestone which is mainly worked for aggregate grade mineral. The end market for industrial dolomite products is international due to the scarcity of this high quality mineral.

4.81. No industrial dolomite is currently worked in Nottinghamshire although there are known reserves in a small area near Holbeck village. Just across the County boundary at Whitwell in Derbyshire industrial dolomite is quarried alongside aggregate stone on a large scale. Typically around 1 million tonnes are extracted every year at this quarry with the tonnage being split evenly between the industrial grade and aggregate limestone. The industrial dolomite is processed into a range of refractory and other products in the on-site kilns and then exported to 28 countries spanning 4 continents.

(3) Policy MP9: Industrial Dolomite Provision

Proposals for industrial dolomite extraction will be supported where a need can be demonstrated.

Justification

4.82. There is no national demand forecast or local apportionment for industrial dolomite. However, the NPPF states that Minerals Planning Authorities should plan for a steady and adequate supply of industrial minerals. Given the scarcity of the resource and the international market it supplies it will be important to work with Derbyshire County Council in relation to the existing site at Whitwell Quarry, to ensure that this can be achieved.

4.83. Existing permitted reserves at Whitwell quarry in Derbyshire are expected to be adequate until 2033 for industrial dolomite and 2040 for aggregate grade limestone, however due to operational requirements further reserves are likely to be needed before this date to maintain future production.

4.84. No site specific proposals for Industrial Dolomite were put forward for consideration as part of the evidence gathering process. As a result a criteria based policy is being proposed.

4.85. The known industrial dolomite reserve in Nottinghamshire is located close to Creswell Crags which is categorised as a Scheduled Ancient Monument, a Site of Special Scientific Interest and forms part of the Registered Park and Garden of Welbeck Abbey. The Crags are also identified on a short list for a potential future World Heritage Site. Therefore any proposal would require careful consideration of the potential impacts on the historic environment offset against the international need for the mineral.

MP10: Building Stone Provision

Introduction

4.86. The continued quarrying of local building stones play an important role in helping to preserve the historic environment and enhancing the local distinctiveness of an area. Local stone is needed to allow existing historic buildings to be properly repaired and it also means new buildings in historic areas can blend in more effectively. The only permitted building stone quarry in Nottinghamshire quarries Bulwell Stone, a buff coloured limestone used as a building stone and more widely as a walling stone used to front many older properties in Nottingham and its suburbs.

Policy MP10: Building Stone Provision

-

The extraction of building stone at the following permitted site will be utilised to maintain future supply:

MP10a Yellowstone Quarry

- Proposals for the extraction of building stone outside the permitted site identified above will be supported where it can be demonstrated that extraction will be primarily for non-aggregate use.

Note: The above site is shown on the Policies Map

Justification

4.87. National policy is reflected through Strategic Objective 7 (page 15), in that the identification of building stone quarries should be supported to ensure that adequate provision can be made to help conserve the historic built environment and local distinctiveness. Yellowstone quarry at Linby has planning permission to extract building stone but it is currently inactive. If reopened this could provide building stone to serve the local market and is the only such quarry in Nottinghamshire. (see appendix 3 – insert 11).

4.88. To date no other sites have been put forward, however demand for a specific building stone could drive the need to develop a new quarry. In this instance criterion 2 in policy MP10 will be used to assess future applications at other sites to ensure that the specialised resource is not used for aggregate purposes. This is in line with national requirements to make the best use of the limited resources to secure long term conservation.

4.89. In demonstrating a need, regard should be had to the Strategic Stone Study for Nottinghamshire (2013). This was undertaken by the British Geological Survey (BGS) and highlights the wide variety of local stones that have been quarried in the past. Evidence of this historic working may help to identify potential sources of these materials. These stones are a key component of the County's local distinctiveness and maybe required in the future for historic building repair or to allow sympathetic new development in historic areas.

MP11: Coal

Introduction

4.90. Most of Nottinghamshire's coal resources are deeply buried and have to be exploited by deep coal mining. It is only in the far west of the County along the Erewash Valley where the coal measures are exposed, that surface (opencast) extraction is possible. The last deep mine in Nottinghamshire located at Thoresby Colliery closed in July 2015. A proposal to work surface mined coal at Shortwood Farm near Cossall has planning permission but has yet to be worked. (see Plan 4).

Colliery tipping

4.91. When coal is mined, a considerable amount of waste spoil is removed, which has to be disposed of. Due to the closures of the remaining collieries in Nottinghamshire, it is unlikely that any additional land will be required for spoil disposal over the plan period. If in the future new coal reserves are exploited this may be a significant consideration for any new proposal.

Coal recovery

4.92. Historical coal processing was often inefficient and substantial quantities of coal were left in the spoil. At some sites it may now be economic to recover this coal, which can amount to several hundred thousand tonnes in a single large tip. Coal recovery involves the re-excavation of spoil for processing, the remainder of which is then re-deposited within the original tipping area. The last tip to be worked in this way was Langton Colliery tip near Kirkby in Ashfield, between 2011 and 2013 (see Plan 4).

(2) Policy MP11: Coal

-

Permission for the extraction of coal will only be granted where:

- the proposal is environmentally acceptable, or can be made so by mitigation; or

- the proposal provides national, local or community benefits which clearly outweigh the likely adverse impacts.

Along with the above the following will be taken into account:

Surface mined coal: Incidental mineral extraction

- Where proposals for surface mined coal are acceptable, proposals for the recovery and stockpiling of fireclays and other incidental minerals will be supported where this does not result in any unacceptable environmental or amenity impact.

Colliery Tipping

-

Proposals for colliery tipping will be supported where:

- a need can be demonstrated; and

- the proposal is environmentally acceptable.

Reworking colliery spoil tips/lagoons

- Applications will be supported for the reworking of colliery spoil tips/lagoons where the environmental and economic benefits of the development, including addressing the likelihood of spontaneous combustion and substantial environmental improvement of the site, outweigh the environmental or amenity impacts of the development or the loss of established landscape and wildlife features.

Justification

4.93. National guidance sets out that permission should not be granted for the extraction of coal unless the proposal is environmentally acceptable, or can be made so by planning conditions or obligations or if it is not environmentally acceptable where national, local or community benefits clearly outweigh the likely impacts. There are no production targets as the Government believes this is a matter for the markets reinforced by long term policy measures.

4.94. Although it is unlikely that additional colliery tipping will be required during the plan period, this activity can have significant impacts in terms of land take and visual prominence. Should proposals for future coal extraction come forward, these will need to be accompanied by details of how the spoil would be managed.

4.95. The reworking of colliery spoil tips and lagoons is in principle a sustainable activity as it recovers coal that has been discarded as waste and it can provide an opportunity to properly reclaim old tips/lagoons that may have been left in a poor state. However, it can also have a significant impact on the environment in terms of visual intrusion, traffic movements, noise and dust. These impacts have to be weighed against the benefits, which could include opportunities for landscape or habitat enhancement.

MP12: Oil and Gas

Introduction

4.96. Oil and gas (Hydrocarbons) are the most important energy minerals produced and consumed in the UK. In 2014, 81 million tonnes were produced in the UK, whilst 132 million tonnes were consumed[2].

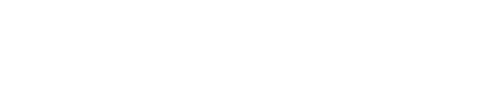

4.97. Historically, two main forms of hydrocarbons have been worked in Nottinghamshire; oil and mine gas. However other potential sources such as coal bed methane and shale gas (unconventional hydrocarbons) are being explored and could be worked over the plan period. Plan 4 identifies the known hydrocarbon resources and existing permitted sites in Nottinghamshire.

Oil

4.98. Oil has been extracted on a small scale since the Second World War when oil reserves in deeply buried sandstones were identified at Eakring. Since then further oil fields have been identified, mostly in north Nottinghamshire, but also as far south as Rempstone near the boundary with Leicestershire. The oil recovered in Nottinghamshire is of high quality and mainly used in the plastics and chemical industries rather than as a fuel. Most is taken by rail from the central collecting station at Gainsborough to refineries at Immingham, Humberside.

Mine gas

4.99. Mine gas refers to the methane that is released from coal seams during deep mining. When mining ceases and ventilation shafts are closed, this gas can fill the mineshafts and other voids and can escape to the surface where it can pose a threat to health and safety in the locality. The situation has become much more prevalent recently because of the number of Nottinghamshire collieries that have closed over the last 30 years. Mine gas can be recovered and burnt to generate electricity.

Coal bed methane

4.100. Coal bed methane extraction involves removing methane directly from the coal seam without mining the coal. The industry is most developed in the USA, whilst in the UK and Europe it remains in its infancy. Interest is however developing and it could become a significant energy source for the future. In Nottinghamshire several proposals for coal bed methane exploration have been granted planning permission. Nearly all of Nottinghamshire overlies a potential coal bed methane resource but the most promising prospects are believed to exist in the eastern half of the County due to the geological formation.

Underground coal gasification

4.101. Energy can also be recovered from coal in the ground by a process known as 'underground coal gasification'. This burns the coal underground using steam/water and oxygen to generate hydrogen, carbon monoxide and methane. It generates far more energy than coal bed methane which does not extract any energy from the solid coal itself. This technology has not been applied to any significant extent and the prospect of this technology being developed remains uncertain.

Shale gas

4.102. Vast quantities of methane exist in many shale deposits worldwide and recent technological advances have now made it economically possible to exploit them. The technology and exploitation of shale gas is most advanced in the USA where it has gone through a period of very rapid development and is now exploited on a very large scale. The UK also has a significant, but largely untested potential shale gas resource. In Nottinghamshire, potential shale gas resources are thought to exist in deeply buried shale deposits found in the far south and north of the County.

4.103. Shale gas extraction involves vertical and horizontal drilling to reach the shale rock formation. A mixture of water, sand and additives is then pumped under high pressure into the bore hole to fracture the rock (a process known as 'fracking'). The gas trapped in the rock is then released and can be collected.

(19) Policy MP12: Oil and Gas

-

Exploration and appraisal of oil and gas will be supported, provided the site and equipment:

- Are not located in a protected area other than in exceptional circumstances where this does not compromise the reasons for the designation and the need for development can be demonstrated; and

- Are located where this will not have an unacceptable environmental impact.

-

The commercial production of oil and gas will be supported, provided the site and equipment:

- Are not located in a protected area other than in exceptional circumstances where this does not compromise the reasons for the designation and the need for development can be demonstrated; and

- Are located at the least sensitive location taking account of environmental, geological and technical factors.

- Proposals at each stage must provide for the restoration and subsequent aftercare of the site, whether or not oil or gas is found.

Justification

4.104. One of the most serious energy issues facing the UK is the expected rapid decline in domestic oil and gas production as our offshore reserves are depleted. By 2020, the UK could be importing around three quarters of its primary energy needs. High energy prices and the need to maintain long-term energy security, mean there is a national need to explore and develop new domestic sources of oil and gas. This includes previously untapped resources such as coal bed methane and shale gas, both of which are known to exist in Nottinghamshire. The capture and use of mine gas from abandoned mines is also encouraged.

4.105. The NPPF states that for oil and gas including unconventional hydrocarbons, minerals planning authorities should develop criteria-based policies that clearly distinguish between the three phases of development (exploration, appraisal and production) and to address constraints that apply within licensed areas.

4.106. The initial exploration phase seeks to establish whether oil and gas are present and may involve seismic surveys, exploratory drilling or hydraulic fracturing. Appraisal is the next phase to find out the extent and quality of the deposit. This could include additional seismic work, drilling additional wells, further hydraulic fracturing and flow tests to establish the economic viability of the resource and its potential productive life. The production phases normally involves drilling a number of wells. This could be those used during earlier exploration and/or appraisal or wells at a new site. Associated equipment such as pipelines, processing facilities and temporary storage tanks are also likely to be required.

4.107. The Planning Practice Guidance states that existing hydrocarbon developments, along with Petroleum Licence Areas should be identified in local plans (see plan 5). Site specific allocations can be included in the local plan if put forward by the industry, however no such sites were put forward as part of the 'call for sites' exercise undertaken as part of the evidence gathering process.

4.108. It is considered that there is no justifiable reason in planning policy terms to separate shale gas from other hydrocarbon development. All hydrocarbon development has the potential to deliver national energy requirements but should be subject to environmental safeguards. Applied to the local circumstances of the Minerals Local Plan, the assessment of environmental and amenity impact (i.e. the constraints on hydrocarbon development) is covered by and can be delivered through the application of the development management policies. Separate legislation also identifies certain requirements in relation to protected groundwater areas or other protected areas[3].

4.109. Oil and gas extraction can only take place in areas where the Oil and Gas Authority has issued a Petroleum Exploration and Development License (PEDL) under powers granted by the Petroleum Act 1998. The current licensed areas are shown on the policies map.

4.110. A UK Petroleum Exploration and Development Licence (PEDL) allows a company to pursue a range of oil and gas exploration activities, subject to necessary drilling/development consents and planning permission.

4.111. Planning permission is one of the main regulatory requirements that operators must meet before drilling a well for both conventional and unconventional hydrocarbons. The County Council is responsible for granting permission for the location of any wells and well pads, and will impose conditions to ensure that the impact on the land is acceptable. However, it is not the only regulatory body that permission for extraction is required from. They include:

- The Oil and Gas Authority issues PEDL, gives consent to drill under the Licence once other permissions and approvals are in place, and have responsibility for assessing risk of and monitoring seismic activity, as well as granting consent for flaring or venting;

- Environment Agency (EA) – protect water resources (including groundwater aquifers), ensure appropriate treatment and disposal of mining waste, emissions to air, and suitable treatment and manage any naturally occurring radioactive materials;

- Health and Safety Executive (HSE) – regulates the safety aspects of all phases of extraction, in particular responsibility for ensuring the appropriate design and construction of a well casing for any borehole.

4.112. A Frequently Asked Questions (FAQ) document on unconventional hydrocarbons has been produced by the County Council and can be found on the Council's website.

Plan 5: Coal and hydrocarbons

[1] UK Minerals Statistics Yearbook 2011 British Geological Survey 2012, page 12

[2] UK Minerals Statistics Yearbook 2015 British Geological Survey, page 58-59

[3] The Onshore Hydraulic Fracturing (Protected Areas) Regulations 2016